Helping Alternative Proteins

Take the Next Leap

Consumption of alternative proteins is becoming widespread, and growing demand for products is leading companies to take production to the next level.

Scaling to commercial manufacturing is a challenging step for startups in the alternative protein space transitioning from development and small scale production to large volumes.

Ready to leap to large scale production?

GET IN TOUCH

MGT is one of the only companies with proven expertise in design,

fabrication and installing cellular

agriculture production facilities

MGT offers profound experience in planning, designing and constructing processing plants in the food, chemical, cosmetics, ink & paint industries.

Our turnkey solutions have been part of the production process of dairy products, juice, egg products, and gravy.

MGT brings extensive experience in dealing with complex processes, custom made systems, monitoring & control system integration.

MGT has been building reactors, mixing systems, and production facilities in food, biopharma, and biological driven industries for the past half-century.

Markets

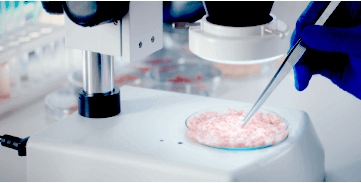

| Cell Culture |

|---|

|

|

Cultured meat will become a significant share of the overall protein market. Taking it from lab to commercial-scale production requires a steep learning curve. MGT BIO stands out in this field as one of the single companies with experience in building a full-scale production line for cultured meat production. Our knowhow and customizable solutions will shorten your time-to-market, and help you realize your full production potential faster than others. |

| READ MORE |

|

Interested in more |

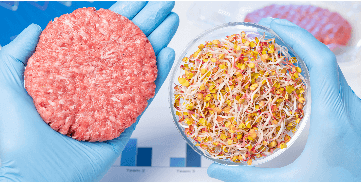

| Plant Based |

|---|

|

|

If your products are based on plant proteins, production lines surely involve processing, cooking, and perhaps even 3D printing of multiple plant ingredients. At MGT BIO we build automated lines which include tanks, reactors, heat exchangers, pumps, piping, valves, and sensors, and provide you with process-control software that guarantees even the most complex processes run smoothly and successfully. |

| READ MORE |

|

Interested in more |

| Fermentation |

|---|

|

|

The process of fermenting using agents such as bacteria, yeast, or fungi requires very specific conditions in every application. At MGT BIO we help you scale your production to mass-market levels by developing high-volume fermentation lines that maintain your product integrity. |

| READ MORE |

|

Interested in more |

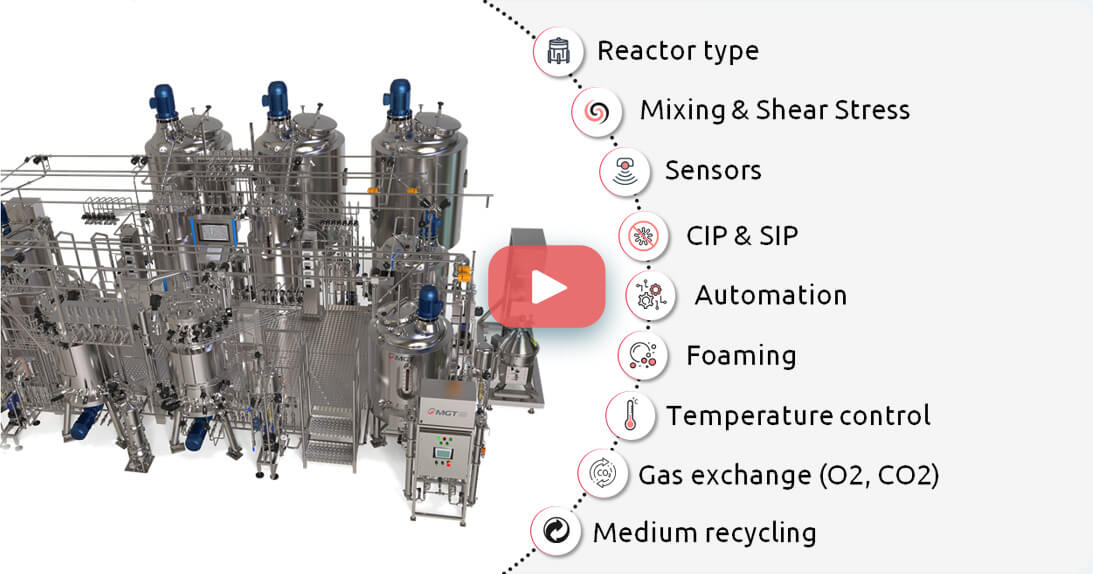

Components

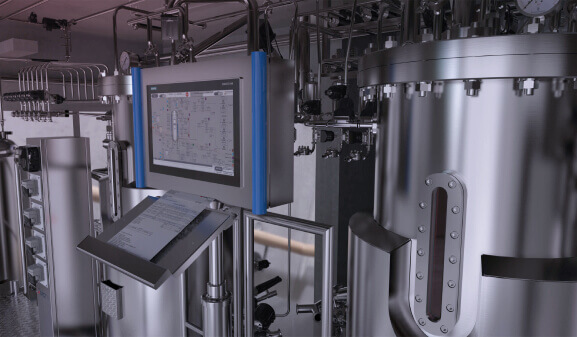

MGT BIO’s process control software is designed for bioreactor and fermenter systems.

It includes verified and validated modules that allow controlling a precise process according to specific requirements. The same control system can be used for one or multiple bioreactors and is easily interfaced with any additional equipment, allowing control of the entire process- upstream and downstream- from a single interface.

MGT BIO software includes:

Control the process temperature and supply fast heating/cooling for the sterilization process

Gear motor for optimizing agitation speed.

Double mechanical seal with sterile liquid lubrication system

Sterilizable while process in operation

Monitor and control the process.

Retractable housing for calibration/maintenance while process in operation

The heart of the system

Case study

An Israeli based biotechnology start-up producing cultivated meat.

Developing a production line to support full commercialization of the company’s products.

Scaling a fed-batch process which involves adding fresh ‘feeds’ of nutrients throughout the run to allow additional cell growth which results in higher product yield, followed by continuous profusion, including media treatment and recycling.

The first of its kind facility that can produce a commercial scale of cultured meat.

Homogenous mixing with no damage to cells

Precise process control in low and high cell densities

Temp control:

∆(T) < 0.1 °C

DO Control:

∆(DO) < 0.5%

pH control:

∆(pH) < 0.01

Fully automatic CIP (clean in place) process and SIP (sterilization in place)

Automatic continuous makeup media process

Integration with customer systems

MGT Bio is part of the MGT Group of companies. Our multidisciplinary in-house team excels at integrating the best available technologies and production techniques into cost-effective, reliable solutions.

We specialize in designing and manufacturing stainless steel reactors, bioreactors and fermenters, advanced mixing systems, and complete process solutions for various applications in biotech, food & beverages, dairies, cosmetics and other industries.

We’d love to hear from you.

Fill the form or drop us a line at [email protected]

The email has been sent